Often regarded as the basis for a vehicle concept, the powertrain refers to all components of a vehicle that transmit torque from the engine to the road. In order to optimize the configuration and interaction of the individual elements and make them more efficient, MANNER offers you the most precise measurement applications based on non-contact sensor telemetry.

Telemetry measurement systems for higher requirements

Powertrain Applications

Our proven measuring systems, which are used to determine torque, temperature, axial pressure, speed, vibration and power, are successfully applied and used on a wide variety of powertrain components. They represent an important tool for ensuring operational stability.

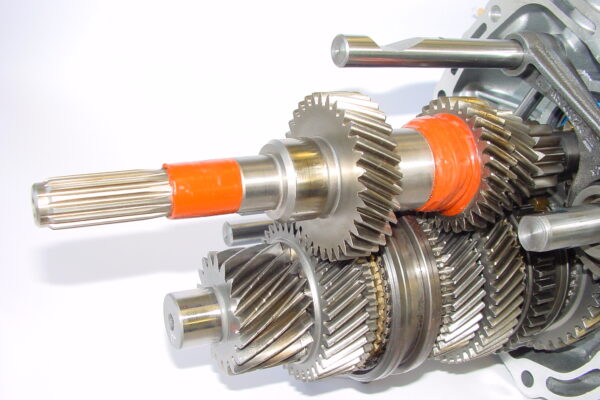

Gearbox

Gearbox Applications

For the design of the drive train and the optimization of the engine control system, the recording of the dynamic torque between the engine and a control gear on a passenger car is of increasing importance. Calculated torque data from engine controls often proved to be unreliable. The MANNER company has developed a special technology for refining the transmission input shaft to a high-quality torque transducer with accuracy class 0.1.

Despite the tight installation conditions, the input shaft does not have to be changed due to the new flex technology. This does not change the mechanical strength and vibration behavior.

The core piece is the particularly flat torque measuring device based on flex technology. The sensor signal booster is literally wound around the shaft. The entire device can be realized with a construction height of only 2.5mm. The measurement data of the strain gage-based transducer are transmitted contactless via the proven digital sensor telemetry technology with 16-bit resolution from MANNER. A special feature is the high temperature resistance of up to 160 °Celsius and the high operational stability during operation.

Side Shaft

Side Shaft Applications

The side shaft represents the dynamic connection between the gearbox and the drive wheels. It transmits power with simultaneous movement of steering and suspension. With its two constant velocity joints, it acts in parallel as a vibration damper. Each side shaft has a fixed joint on the wheel side and a sliding joint on the gearbox side, both of which are connected by the so-called intermediate shaft.

Our latest generation of sensor telemetry for the side shaft helps you to accurately measure torque and dynamic drive power as well as their transmission. Do justice to the key role of the side shaft and optimize its effects on efficiency, dynamics, noise, vibration and driving behavior with the aid of MANNER sensor telemetry. Weight optimization and service life are also of paramount importance.

Cardan Shaft

Cardan Shaft Applications

Benefit from our ongoing activities to research and develop the latest measurement methods using near-field telemetry. You can rely on our many years of experience in the field of measuring applications on drive shafts.

Clutch

Clutch Applications

The vehicle coupling transmits torque from the engine to the transmission and enables the gear stages to be started and changed in all torque ranges.

Whether for foot-operated vehicle clutches or automatic clutch systems, MANNER’s telemetry applications provide precise information on decision-relevant measurement data.

Our competence in terms of precise measurement data recording on clutch components is reflected in the following areas:

- Temperature distribution on clutch discs/clutch plates

- Dynamic clutch disc/plate spacings

- Dynamic torque on clutch discs/clutch plates

- Dynamic torsion angle detection

- Number of channels: 1-48

- Sample rate per channel: 15 samples/s

- Integrated sensor signal booster

- Sensor: NiCr-Ni thermocouple (type K)

- Contactless transmission of measured values

- Zero drift: <± 0.01%/°Celsius

- Ambient temperature Sensor signal booster: -25° … 180°Celsius

- Maintenance-free due to inductive energy and data coupling

- Signal bandwidth: 30 Hz

- Digital transmission

- Signal resolution: 16 Bit

- Integrated cold junction compensation

- Number of channels: 1-4

- Sampling rate per channel: 4000 samples/s

- Integrated sensor signal booster

- Sensor: Magneto-inductive distance sensors

- Contactless transmission of measured values

- Zero drift: <± 0.01%/°Celsius

- Ambient temperature sensor signal booster: -25° … 160°Celsius

- Maintenance-free due to inductive energy and data coupling

- Digital transmission

- Signal resolution: 16 Bit

- Integrated cold junction compensation

Wheel and Brake

Applications on Wheels and Brake Discs

Whether for steel or light alloy rims, MANNER Sensortelemetrie GmbH offers you the optimum applications and products for your torque, vibration and temperature measurement on wheels and brake discs.

Lightweight and 100% waterproof, our digital systems transmit precise measurement data inductively, even by radio if you do not want a mounting device.

With low power consumption and reliable data transmission, even at long ranges, MANNER offers you solutions for current and future challenges for your measurements on wheels, rims and brake discs.

Torque measuring discs:

- lightweight, waterproof and extremely robust

- Integrated sensor signal booster

- Sensor: Strain gauge

- Measuring range: 500 Nm – 5 kNm

- Contactless transmission of measured values

- Accuracy: 0.1%.

- Construction height: 20 mm

- Bandwidth per channel 1kHz (-3dB)

- Ambient temperature Sensor signal booster: -30° … 125°Celsius

- Maintenance-free due to inductive energy and data coupling

- Digital transmission

- Signal resolution: 16 Bit

The ProductAssistant

In a few steps to the optimal measuring system. Our product experts configure the optimal system composition according to your requirements and will be happy to prepare an individual offer for you.