As complex and specific as industrial plants and production facilities are structured, MANNER manufactures the appropriate measuring applications for tough continuous operation. In the field of oil-free gas and air compression as well as in the application field of extruder screws, the most accurate recording of torques, forces and temperatures is ensured by the contactless transmission of measurement data in our sensor telemetry applications. Long-term monitoring of extruder shafts thus becomes as easy as automated machine monitoring of thermal loads.

Telemetry measurement systems for higher requirements

Process Monitoring and OEM

MANNER Sensortelemetrie GmbH offers miniaturized applications for the monitoring and protection of automated production plants for the detection of a wide range of drive powers. In this way, production operations can be stopped automatically and without disturbance if the load limits of individual components are exceeded. Our company develops such early damage detection and damage prevention devices for a wide range of production plants in a variety of industries and manufacturers. In this form, MANNER’s easy-to-install measuring systems make a decisive contribution to optimizing the service life, strength, efficiency and effectiveness of production plants.

Extruder

Extruder screws

Extruders are widely used in the industrial production of plastics, food and cosmetics. In addition to the simple single-screw extruders, the twin or multi-screw extruders require a complex gear unit to drive the extruder screws rotating in opposite or the same direction.

Increasingly sophisticated extruder shapes require gear technologies that transmit the highest torques evenly to all screw shafts in the smallest of spaces. The actual torques at the screws and the exact distribution of these to the individual extruder shafts can be precisely measured using MANNER’s sensor telemetry.

Finally answer critical questions regarding your extrusion operation, such as:

- Which torques must the screws actually cope with?

- Is the load distribution evenly distributed over all screw shafts?

- Can the extruder control system be better adapted to the torques and forces occurring?

- How does the extruder and its individual screw shafts behave in different production conditions?

We apply your coupling sleeves to the drive shafts with the tried and tested sensor telemetry for extruder shafts and the proven MANNER sensor technology records the real torques where they occur. These are transmitted contact-free via an induction antenna to a corresponding evaluation unit, your computer or your control system. In addition, specially developed software records the measured values, for example for long-term monitoring.

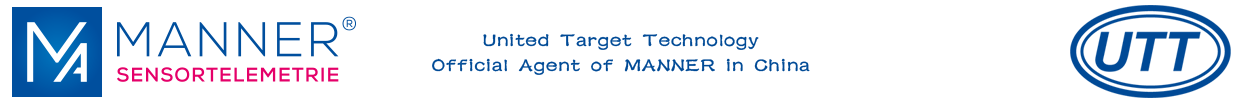

Gas Compression

Gas Compression

For many industrial applications, oil-free gas and air compression has proven to be an elementary process component. Quality, energy optimization and 100% availability are extremely important for the process.

MANNER’s measuring systems are successfully used to maintain operating pressures and air or gas quantities emitted per time unit constantly and reliably. As process-specific as compressors and compression systems are designed, MANNER manufactures the appropriate measuring application for tough continuous operation. The most precise recording of speeds, forces, torques, power, temperatures and distances is ensured by the contactless transmission of measurement data in our sensor telemetry applications.

As the generation of high-quality compressed gas or compressed air is indispensable for the performance standards of numerous processes, MANNER is constantly developing new measuring applications to refine these systems. Optimize the reliability, economy and energy efficiency of your compressed gas / compressed air supply with our help. Regardless of whether you are a user or producer of compression systems, our competent team of engineers will work out the ideal solution for your measuring task.

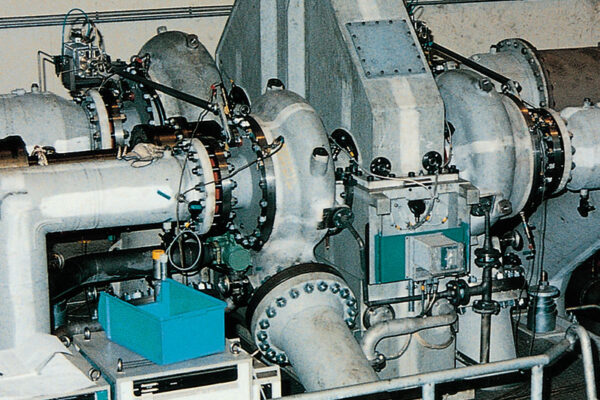

Rotor Temperature

Rotor Temperature monitoring

The temperature measurement of the rotor or its windings plays a decisive role in the safe operation of (large) electric motors and generators. When converting kinetic energy into electrical energy or vice versa, it is urgently necessary to avoid thermal overloads and their devastating consequences. Furthermore, from an economic point of view, it is desirable to extend the replacement and maintenance intervals or to adapt them to the specific load situations.

With the help of MANNER Sensortelemetry, measuring the rotor temperatures becomes child’s play. To protect against exceeding the permissible rotor and winding temperatures, we have been working for many years with manufacturers and operators of electric motors and generators to optimize the monitoring of thermal loads. Furthermore, you are thus able to match the maintenance of your rotor configuration to the real demands and automate the monitoring processes.

In doing so, we guarantee the highest immunity to interference in data transmission; even in extreme electromagnetic interference environments. Our rotor temperature recording systems based on non-contact sensor telemetry are used successfully worldwide in power plants, railway converters, steelworks, oil pumping stations, etc.

Load Limitation / Load Monitoring

Load Limitation / Load Monitoring

MANNER Sensortelemetrie GmbH offers miniaturized applications for monitoring and protecting automated production facilities to record a wide range of drive power. Thus, production operation can be stopped immediately and automatically if load limits of individual components are exceeded.

MANNER develops such early damage detection and damage prevention devices for a wide range of production plants and manufacturing processes. Evaluate the accurate measurement data for critical components of your production operation and optimize your systems for service lifestrength, efficiency and thus efficiency.

Benefit from the advantages of MANNER sensor telemetry:

- Precise recording of torques, bending moments, temperatures, pressure and tensile forces at highest speeds

- Contactless data transmission by means of inductive coupling

- Simple evaluation of the measurement data via evaluation unit and specially programmed telemetry software from MANNER

- High accuracy and security of the digital measurement data

- High temperature stability

- Miniaturized and low-weight design

- Extremely low installation effort

The ProductAssistant

In a few steps to the optimal measuring system. Our product experts configure the optimal system composition according to your requirements and will be happy to prepare an individual offer for you.